Lago Lithium Brine Project

Lago Lithium Brine Project

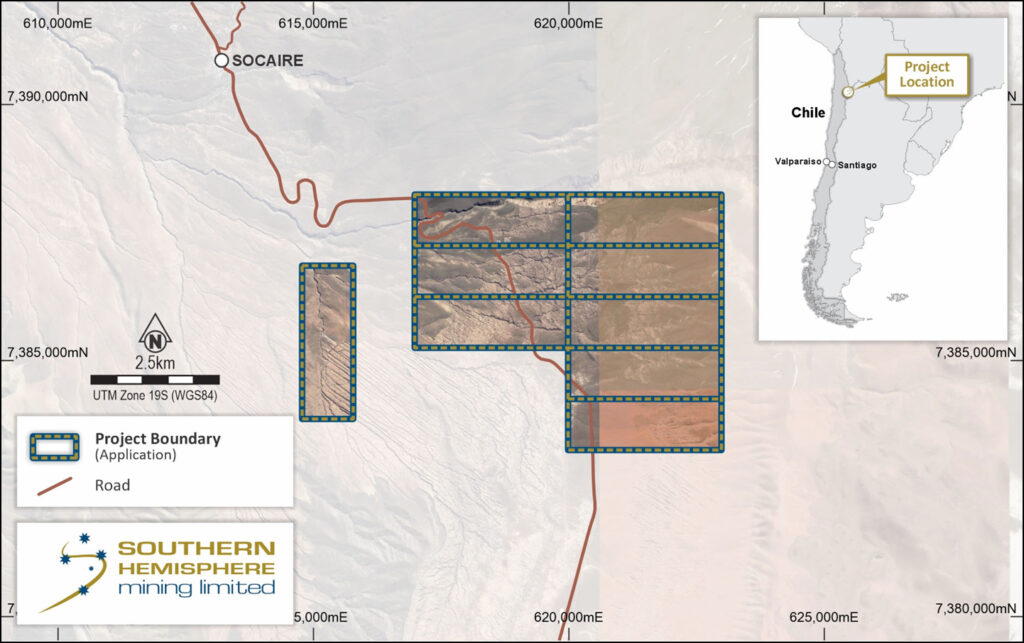

Figure 1: Location of the nine new lithium brine concessions

![]() In July 2023 – Southern Hemisphere Mining Limited announced the application for the Lago Lithium Brine Project (‘Lake’ in Spanish), with the project located in the renowned lithium-rich Atacama region of Chile.

In July 2023 – Southern Hemisphere Mining Limited announced the application for the Lago Lithium Brine Project (‘Lake’ in Spanish), with the project located in the renowned lithium-rich Atacama region of Chile.

The Salar de Atacama is widely recognised for its exceptional lithium deposits operated by the world’s largest lithium brine producers, SQM and Albemarle.

-

The Lago Lithium Brine Project includes nine new concessions and covers an area of approximately 27km².

-

Located near two of the largest lithium operators, SQM and Albemarle, in the renowned lithium-rich Atacama region of Chile.

SQM holds leases in the Salar de Atacama with a total area of approximately 1,400km² and possesses permission to extract brines from an area of approximately 820km². SQM produces highly concentrated lithium chloride at its facility in the Salar de Atacama which are then transported to its PQC lithium carbonate processing facilities near Antofagasta, Chile.

The annual production of the lithium carbonate plant at PQC is 180,000 metric tonnes per year (mtpa) and is in the process of increasing the production capacity to 250,000 mtpa by 2026. (source SQM Technical Report Summary – Operation Report for Salar de Atacama April 2022).

The Company’s concessions were applied for following a comprehensive evaluation process, targeting exploration for lithium brines that are potentially suitable for Direct Lithium Extraction technology (DLE).

They are located in an adjacent sedimentary basin to the Salar de Atacama with excellent road access. (Refer Figure 1). The Company is unaware of any competing application(s) on the public register.

Lithium, a vital component in the production of high-performance batteries for electric vehicles and renewable energy storage systems, has emerged as a crucial resource in the transition to a greener and more sustainable future.

Chile, renowned for its world-class lithium and copper resources, and established mining infrastructure, serves as an ideal location for our expansion efforts. The application for these concessions in the Atacama region, known for its high lithium concentrations and low impurities, gives the Company exposure to a highly prospective lithium investment and reinforces our commitment to sustainability and responsible resource management.

Figure 2: Close up of the nine new lithium brine concessions. Highway 23 provides excellent access to the project area.

Southern Hemisphere is targeting prospects that are amenable to DLE. This technology uses innovative methods to extract lithium from brine sources without the need for extensive evaporation ponds or traditional mining processes. DLE technology offers a more efficient and environmentally friendly approach to lithium extraction, particularly from lithium-rich brine deposits found in regions such as salt flats or salars.

The traditional lithium extraction process involves pumping brine from underground reservoirs into evaporation ponds, where the sun and wind help evaporate the water over a period of several months. This method is time consuming, land-intensive, and can have significant environmental and social impacts, including habitat disruption and water depletion.

DLE technology, on the other hand, aims to minimise these drawbacks by employing more direct and efficient methods of lithium extraction. While there are various DLE technologies in development, they generally involve the following key steps:

Direct Brine Extraction:

Instead of relying on evaporation, DLE technologies focus on directly extracting lithium-rich brine from underground reservoirs using specialised wells or boreholes. These extraction methods are designed to target high-concentration lithium zones, reducing the need for extensive pumping and evaporation.

Selective Lithium Separation:

Once the brine is brought to the surface, DLE technologies employ specific chemical processes or ion exchange techniques to selectively separate lithium ions from the brine. These processes typically involve passing the brine through various filters or ion-selective membranes that capture and concentrate the lithium ions.

Lithium Recovery:

After the selective separation process, the concentrated lithium solution is further processed to remove impurities and other unwanted elements. Various techniques such as precipitation, electrolysis, or solvent extraction may be utilised to isolate and recover pure lithium compounds suitable for downstream applications.

Advantages of DLE technology include:

- Faster Lithium Extraction: DLE methods offer significantly faster extraction rates compared to traditional evaporation methods, reducing the overall production time and allowing for more efficient utilisation of resources.

- Reduced Environmental Footprint: DLE technologies typically require smaller surface areas and do not rely on extensive evaporation ponds, thereby minimising land use and habitat disruption. They also have the potential to consume less water and energy, reducing the overall environmental impact of lithium extraction.

- Scalability: DLE processes can be designed to accommodate a range of production scales, from small pilot plants to large commercial operations, making them adaptable to various project sizes and locations.

- High Purity Lithium Output: DLE methods often yield higher purity lithium compounds, which are desirable for the production of lithium-ion batteries used in electric vehicles and energy storage systems.

While DLE technology shows promise in revolutionising the lithium extraction industry, it is important to note that some DLE processes are still in the research and development phase. However, advancements in this field have the potential to significantly improve the sustainability and efficiency of lithium extraction, supporting the growing demand for lithium in clean energy applications.

Recent changes in Chilean government lithium policy has resulted in a pegging rush in this area and others for lithium prospective targets.

Related News

Quarterly Activity Report for the period ending 31 March 2024

⚒️ Southern Hemisphere Mining Limited reports its Quarterly Activity [...]

Copper and Gold prices moving as Southern Hemisphere Mining wraps 2024 PDAC Conference

⚒️ Southern Hemisphere Mining Limited's flagship Llahuin Copper-Gold Project continues [...]

PDAC 2024 kicks off in Toronto with Southern Hemisphere Mining exhibiting Llahuin Copper at Booth 3242

⚒️ Southern Hemisphere Mining Limited Chairman Mark Stowell and [...]

Llahuin ‘One of the world’s next long-life Copper mines’ – Company Presentation for PDAC 2024

⚒️ Southern Hemisphere Mining Limited releases its updated 2024 [...]

Interview: SUH Chairman talks Copper advancement at the Llahuin Project in Chile for 2024 – Stockhead

⚒️ Southern Hemisphere Mining Limited Chairman Mark Stowell has [...]

Quarterly Activities Report for the period ending 31 December 2023

⚒️ Southern Hemisphere Mining Limited presents the Quarterly Activity [...]