Southern Hemisphere Mining Limited reports on its plan to sustainably develop the 100% owned Los Pumas Manganese Project into a significant, reliable source of Manganese (Mn) to meet the demand and rapid growth in the EV and EV battery metals industries.

Executive Summary

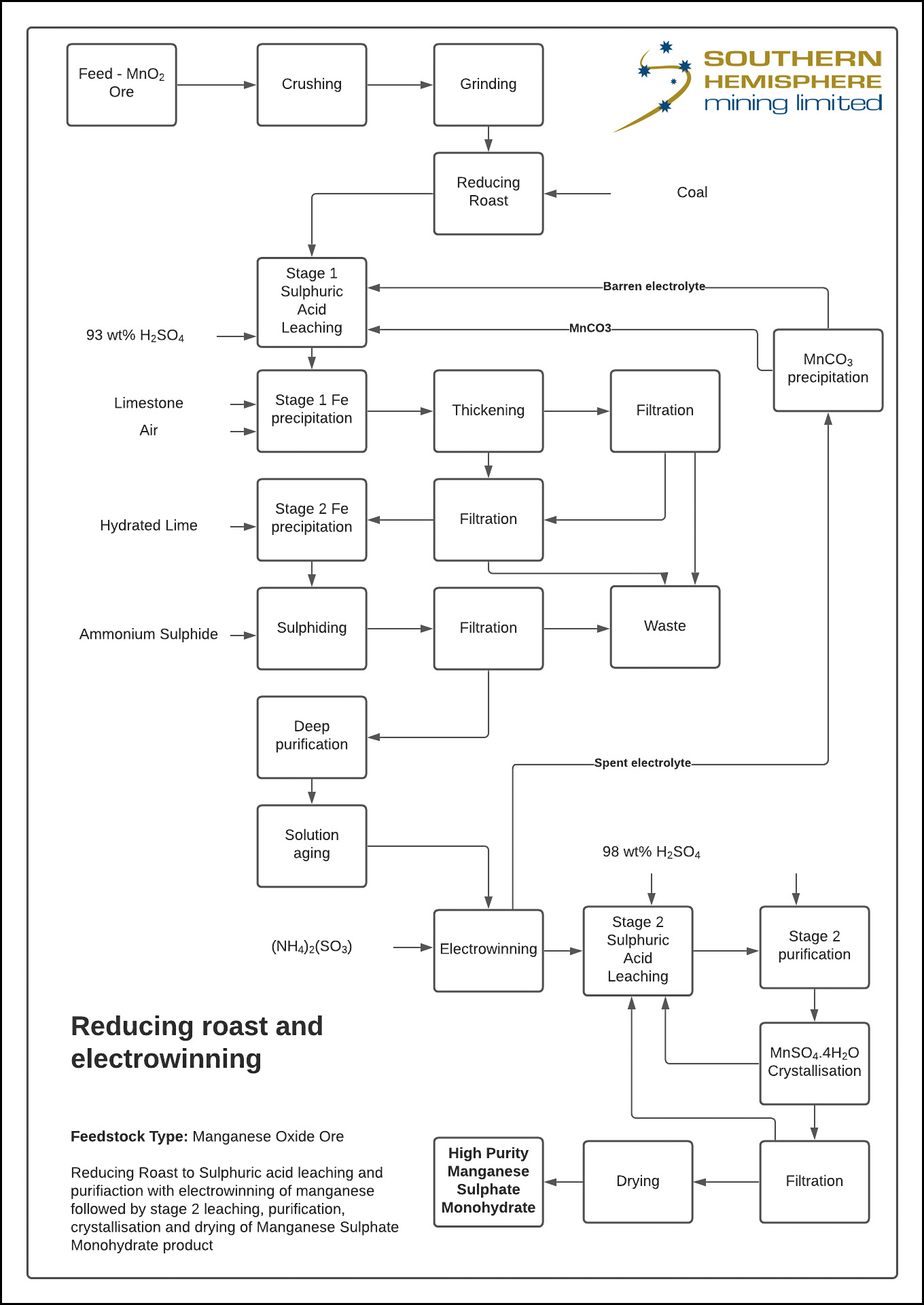

The company engaged industry experts to carry out a review to assess the optimal process flowsheet for production of High Purity Manganese Monohydrate (HPMSM) from Los Pumas material.

The flowsheet analysis has identified that the following additional products could be produced by eliminating different steps in the identified process:

- Electro manganese metal (EMM)/ High purity EMM (HPEMM) – established market.

- Agricultural manganese sulphate monohydrate (MSM) – growing market.

- Agricultural Sulphate of Potash is a by-product of the HPMSM process (SOP – growing market).

The ability to produce a range of different products enhances the robustness of the Los Pumas Manganese Project.

The location of the Los Pumas Manganese Project is optimal for carbon neutral production:

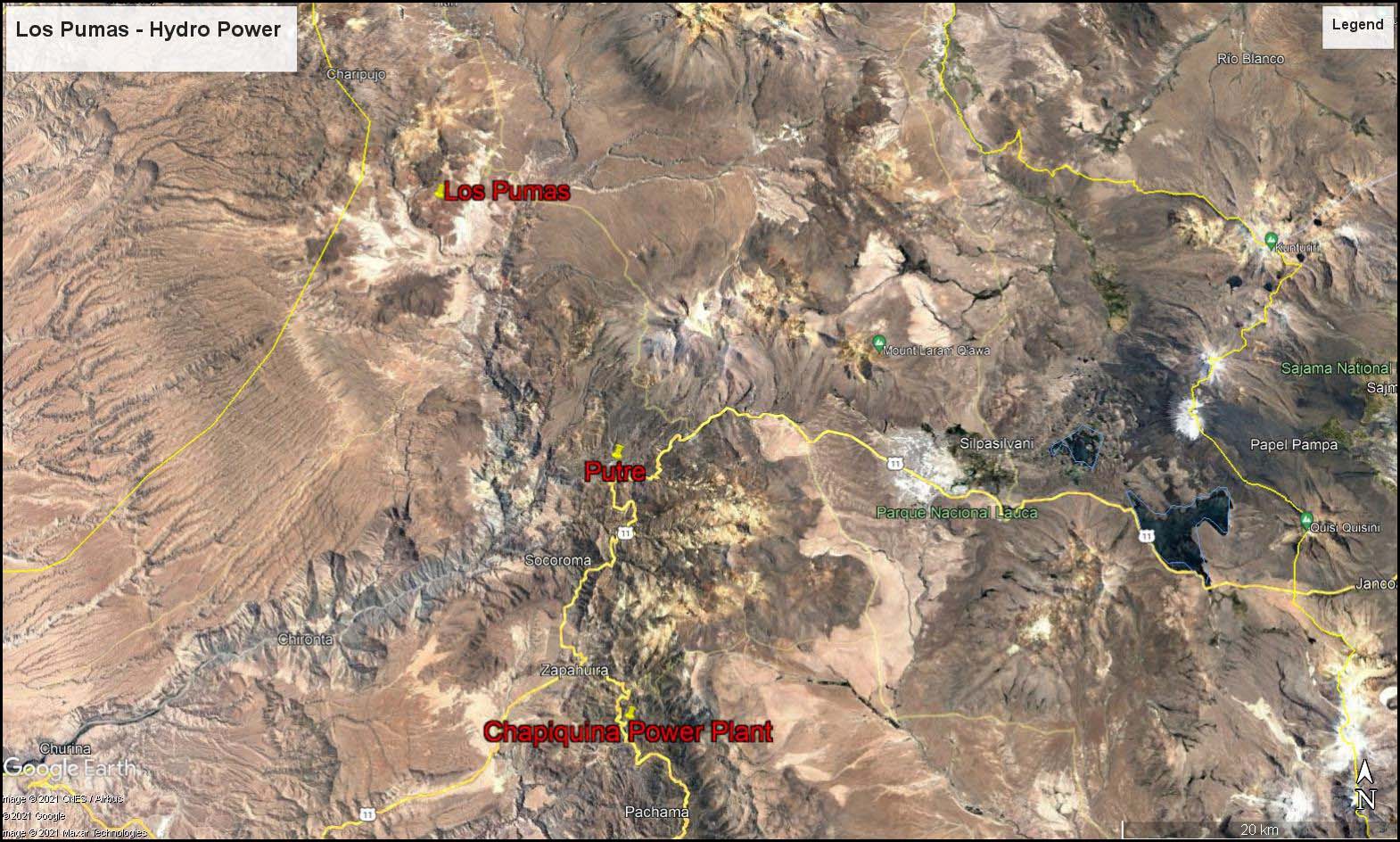

- The Chapiquina Hydroelectric Power Plant ~ 55km via the town of Putre.

- The Arica (Port) – La Paz railway line passes next to the project for low cost/low carbon transport for export from the Port of Arica.

- Location in a low population area.

- Elevation is optimal for added solar power options.

- The town of Putre is 35km away for workers, logistics and equipment support.

Work continues engaging with commodity traders, EV and EV battery manufacturers to advance the Los Pumas Manganese Project with the aim to supply a carbon-neutral battery cathode manganese component.

Production of HPMSM

Three potential process flowsheets were considered:

- Reducing roast and precipitation of MnCO3 intermediate product.

- Reducing leach with precipitation of MnCO3 intermediate product.

- Reducing roast and electrowinning of HPEMM intermediate product.

To evaluate the drivers of production of HPMSM from Los Pumas material the process flow options were modelled using SysCAD steady state simulation software. This aimed to provide an indication of the cost drivers, along with inputs for comparison to produce HPMSM from manganese oxide ore. The analysis was designed as a preliminary check of the viability of recovering HPMSM, along with other potential revenue streams.

The goals of the analysis included:

- Maximise recovery of Mn to HPMSM.

- Minimise consumption of water.

- Minimise reagent consumption.

- Minimise generation of carbon emissions (Hydropower).

Analysis was performed using the proposed Dense Media Separation (DMS) product as beneficiated feed to the HPMSM recovery plant. The option for a reducing roast, sulphuric acid leach and intermediate electrowinning before HPMSM crystallisation proved to be the most efficient process, with the lowest technical risk.

The flowsheet is shown in the figure below:

The details of the results of the process model evaluation are discussed below.

- Recoveries for the reducing roast with precipitation and reducing roast with electrowinning were higher than the reducing leach with precipitation (73% vs 66%), reflecting the assumptions that the reducing roast would be more efficient than chemical reduction of Cryptomelane. The analysis shows potential Sulphate of Potash (SOP) production as a by-product credit.

- Comparing the two flowsheet options showed higher recovery for the reducing roast but the sulphuric acid requirements were lower for the reducing leach, 1.87 t H2SO4 per tonne HPMSM to 1.71. The acid requirements for the Los Pumas material, with Cryptomelane as the primary host, were higher than average.

- Examination of the parameters for using a reducing roast and electrowinning vs reducing roast with precipitation demonstrates that although electricity consumption would be considerably higher, the consumption of sulphuric acid would be reduced.

The results show that if hydroelectricity can be acquired for a reasonable price the electrowinning option with higher recoveries should have lower cost than precipitation options.

Alternative Products

The primary focus of this program has been to assess the options for production of High Purity Manganese Monohydrate (HPMSM) from Los Pumas material. The HPMSM market, while growing is still relatively small and as global growth of the market occurs it would be beneficial to have alternative products to supplement project revenue.

The program has identified that by using the optimal flowsheet the following products could be produced by eliminating different steps in the process.

- Electro manganese metal (EMM)/ High purity EMM (HPEMM) – established market.

- Agricultural manganese sulphate monohydrate (MSM) – growing market.

- Sulphate of Potash (SOP – growing market).

Los Pumas Infrastructure

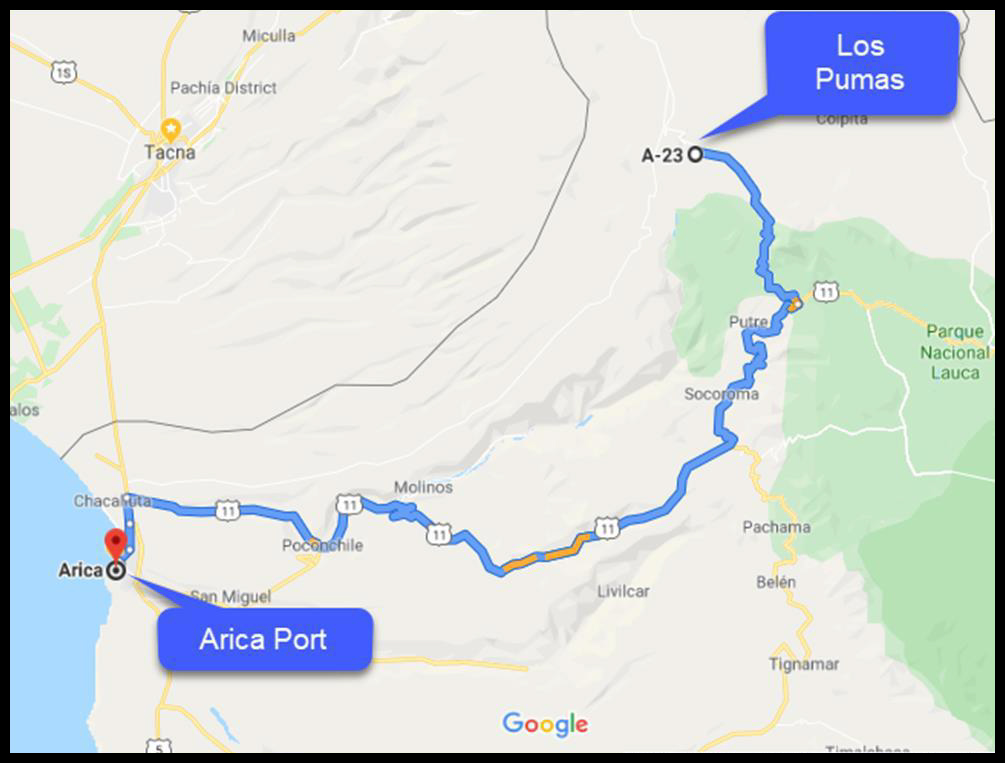

The Los Pumas Project is located in Northern Chile, 175 km from Arica (Port City) which is the major port for Bolivia. The port handles exports and imports of Tin, Steel, Lead concentrate and Soya. Arica is well positioned and is close to the USA west coast and China for optimal end user supply.

The railway line between Arica and La Paz(Bolivia) was refurbished in May 2021 and provides opportunities for lower transport costs.

Los Pumas Project location in Chile.

Train on the Arica – La Paz Railway in May 2021.

The Chapiquina hydroelectric power plant is approximately 25km from the town of Putre, which is the largest town within 35 km of the Los Pumas Project. The power plant injects power into the Sistema Interconectado Del Norte Grande the regional power grid.

Los Pumas location relative to Chapiquina Hydroelectric Power Plant

The Los Pumas Manganese project is well positioned to utilise the local infrastructure available for the project development.

Los Pumas Development Options

The current work adds to the development opportunities for the project, which is well placed to supply Los Pumas processed ore into Nickel Cobalt Manganese (NCM) batteries or similar, aimed at the EV market.

The electrification of the global vehicle fleet requires vast amounts of cathode materials. Batteries are trending toward higher manganese content for safer, more cost effective solutions. Tesla and VW plan to mass produce a new battery with a high proportion of manganese and no cobalt – Tesla approx. 33% Mn and VW greater than 50% Mn. The new cathode designs are expected to reduce costs without compromising performance.

The latest work flowsheet analysis has highlighted an optimal process flow sheet which needs to be validated with additional testwork. The analysis has also provided alternative products which could be produced as the HPMSM market develops.

Note: Process modelling and analysis was undertaken by Dr Will Goodall, Principal Consultant, MinAssist Pty Ltd. Dr Goodall is a metallurgical process consultant with 20 years’ experience in process development and optimisation across a wide range of commodities. With a focus on battery and specialty metals Dr Goodall has undertaken process assessment and development for several battery metal projects, including detailed assessment of alternative feedstocks and process options for production of HPMSM.

More about the Los Pumas Manganese Project here.

News Release

Date: 7 October 2021 | ASX Code: SUH

===

Southern Hemisphere Mining Limited is a successful copper-gold explorer in Chile, the world’s leading copper producing country and one of the most prospective regions of the world for major new copper discoveries.

Southern Hemisphere Mining Limited is a successful copper-gold explorer in Chile, the world’s leading copper producing country and one of the most prospective regions of the world for major new copper discoveries.

For the latest information about the Company – please visit our Latest News and Corporate Profile pages. We are also on LinkedIn and Twitter.